Arduino shield and tidier wires

August 16, 2013 Leave a comment

If you have read some of my previous posts you will know that the state of the wiring on my robot has been causing me distress. It’s not that the wiring was causing issues as such, it’s just that I knew there was a better way of doing it. My design had the Arduino board mounted on the base with many wires connecting it to an interface board mounted on the rear of the robots torso. The better way to do it would be to use a shield that connects to, and sits on top of, the Arduino and mount the Arduino to the rear of the robot torso. So I set about designing and building a shield to meet my needs.

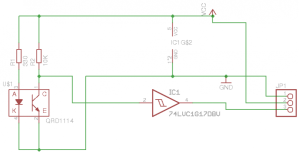

I started with a template made by someone else, no use re-inventing the wheel. I used the one found here http://circuitfun.wordpress.com/2012/01/02/arduino-mega-shield-template-in-eagle-improved/, which I must say is very good! I then added parts to meet my requirements. I added connectors for all of the servos, connected to the PWM pins. I also added connectors from the ADC pins to interface the potentiometers, with a few spare should I wish to connect anything else at a later date. Connectors from a few digital pins allow sonar sensors to be connected as well as the hand switches. As a bonus I added the servo power switch circuit to the shield so I could do away with the small separate circuit that was performing this task. I then completed the board layout and fabricated the board.

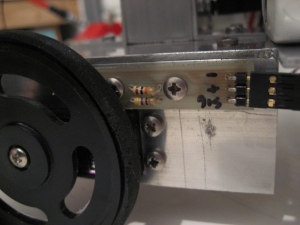

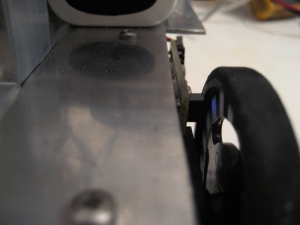

Having completed the board and tested it I would say it was a worth while project. I have got rid of a load of wires from the rear of the robot and cleared some space on the base of the robot. I did have the batteries slung beneath the base which I didn’t like, so these have moved to the top of the base. All in all, this set-up is much tidier and this makes me happy. The picture below shows the Arduino and shield in situ.